Power Cables with Concentric Outside Conductors

(NYCY , N2XCY)

| No. & Nominal Cross Section of the Conductors (mm²) | Nominal Insulation Thickness (mm) | Nominal Inner Covering Thickness (mm²) | Cross Section of Concentric Conductors (mm²) | Nominal Sheath Thickness (mm) | Average Outer Diameter (mm) | Max.Conductor Resistance in 20℃ (Ω / Km) | Approx. weight (Kg / Km) |

|---|---|---|---|---|---|---|---|

| 1×4 / 4 | 1 | - | 4 | 1.8 | 9.2 | 4.61 | 145 |

| 1×6 / 6 | 1 | - | 6 | 1.8 | 9.9 | 3.08 | 191 |

| 1×10 / 10 | 1 | - | 10 | 1.8 | 11.2 | 1.83 | 277 |

| 1×16 / 16 | 1 | - | 16 | 1.8 | 12.2 | 1.15 | 396 |

| 1×25 / 25 | 1.2 | - | 25 | 1.8 | 14.3 | 0.727 | 588 |

| 1×35 / 35 | 1.2 | - | 35 | 1.8 | 15.4 | 0.524 | 779 |

| 2×1.5 / 1.5 | 0.8 | 1 | 1.5 | 1.8 | 12.5 | 12.1 | 205 |

| 2×2.5 / 2.5 | 0.8 | 1 | 2.5 | 1.8 | 13.3 | 7.41 | 250 |

| 2×4 / 4 | 1 | 1 | 4 | 1.8 | 15 | 4.61 | 341 |

| 2×6 / 6 | 1 | 1 | 6 | 1.8 | 16.1 | 3.08 | 423 |

| 2×10 / 10 | 1 | 1 | 10 | 1.8 | 18.2 | 1.83 | 585 |

| 2×16 / 16 | 1 | 1 | 16 | 1.8 | 21.7 | 1.15 | 864 |

| 2×25 / 16 | 1.2 | 1 | 16 | 1.8 | 24.7 | 0.727 | 1173 |

| 2×35 / 16 | 1.2 | 1 | 16 | 1.8 | 27 | 0.524 | 1450 |

| 3×1.5 / 1.5 | 0.8 | 1 | 1.5 | 1.8 | 13 | 12.1 | 228 |

| 3×2.5 / 2.5 | 0.8 | 1 | 2.5 | 1.8 | 13.8 | 7.41 | 282 |

| 3×4 / 4 | 1 | 1 | 4 | 1.8 | 15.7 | 4.61 | 390 |

| 3×6 / 4 | 1 | 1 | 4 | 1.8 | 16.9 | 3.08 | 490 |

| 3×10 / 10 | 1 | 1 | 10 | 1.8 | 19 | 1.83 | 687 |

| 3×16 / 16 | 1 | 1 | 16 | 1.8 | 22.4 | 1.15 | 1020 |

| 3×25 / 16 | 1.2 | 1 | 16 | 1.8 | 26.1 | 0.727 | 1420 |

| 3×35 / 16 | 1.2 | 1 | 16 | 1.8 | 28.5 | 0.524 | 1781 |

| 4×1.5 / 1.5 | 0.8 | 1 | 1.5 | 1.8 | 13.8 | 12.1 | 259 |

| 4×2.5 / 2.5 | 0.8 | 1 | 2.5 | 1.8 | 14.7 | 7.41 | 324 |

| 4×4/ 4 | 1 | 1 | 4 | 1.8 | 16.7 | 4.61 | 453 |

| 4×6/ 6 | 1 | 1 | 6 | 1.8 | 18.2 | 3.08 | 576 |

| 4×10/ 10 | 1 | 1 | 10 | 1.8 | 20.1 | 1.83 | 810 |

| 4×16/ 16 | 1 | 1 | 16 | 1.8 | 24.2 | 1.15 | 1214 |

| 4×25/ 16 | 1.2 | 1 | 16 | 1.8 | 28.3 | 0.727 | 1715 |

| 4×35/ 16 | 1.2 | 1 | 16 | 1.8 | 31.1 | 0.524 | 2174 |

| 7×1.5/ 2.5 | 0.8 | 1 | 2.5 | 1.8 | 15.5 | 12.1 | 335 |

| 7×2.5/ 2.5 | 0.8 | 1 | 2.5 | 1.8 | 16.6 | 7.41 | 417 |

| 10×1.5/ 2.5 | 0.8 | 1 | 2.5 | 1.8 | 18.4 | 12.1 | 455 |

| 10×2.5 / 4 | 0.8 | 1 | 4 | 1.8 | 20 | 7.41 | 591 |

| 12×1.5 / 2.5 | 0.8 | 1 | 2.5 | 1.8 | 18.9 | 12.1 | 491 |

| 12×2.5 / 4 | 0.8 | 1 | 4 | 1.8 | 20.5 | 7.41 | 645 |

| 14×1.5 / 2.5 | 0.8 | 1 | 2.5 | 1.8 | 19.7 | 12.1 | 541 |

| 14×2.5 / 6 | 0.8 | 1 | 6 | 1.8 | 21.3 | 7.41 | 730 |

| 19×1.5 / 6 | 0.8 | 1 | 6 | 1.8 | 21.4 | 12.1 | 679 |

| 19×2.5 / 6 | 0.8 | 1 | 6 | 1.8 | 23.3 | 7.41 | 906 |

| 24×1.5 / 6 | 0.8 | 1 | 6 | 1.8 | 24.4 | 12.1 | 891 |

| 24×2.5 / 10 | 0.8 | 1 | 10 | 1.8 | 26.7 | 7.41 | 1203 |

| 30×1.5 / 6 | 0.8 | 1 | 6 | 1.8 | 25.6 | 12.1 | 1032 |

| 30×2.5 / 10 | 0.8 | 1 | 10 | 1.8 | 28 | 7.41 | 1402 |

| 37×1.5 / 10 | 0.8 | 1 | 10 | 1.8 | 27.3 | 12.1 | 1269 |

| 37×2.5 / 10 | 0.8 | 1 | 10 | 1.9 | 30.2 | 7.41 | 1698 |

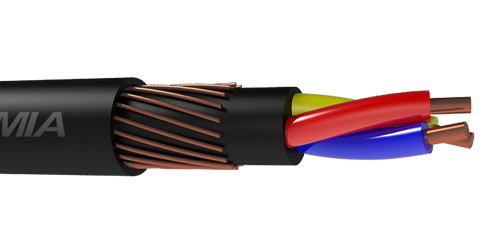

Cable Layer Construction

- Cu/PVC/CWS/PVC

- Cu/PVC/CWS/CTS/PVC

Cable Structure

- Conductor material: Annealed copper conductor according to IEC 60228, class 1 (solid), class 2 (stranded) or class 5 (flexible)

- PVC core insulation: Compound type of PVC/ A.

- Core insulation colors: Up to 5 cores, color or number coding and for more than 5 cores, number coded imprints. For 3 or more cores, the green / yellow earth core is the last core in the outer layer.

- PVC inner covering.

- Concentric copper conductors in inner layer.

- PVC outer sheath: Compound type of PVC/ST1.

- Sheath color is normally black.

- These Types of cables can also be manufactured with aluminium or aluminium alloy conductors, according to IEC 60228.

Application

These types of cables are used for energy supply preferably in underground laying, specially in subscribed networks,

power stations as well as control cables for transmission of control impulses and test data, house connection boxes

and street lighting. Overall, these cables are suitable where increased electrical and mechanical protection is

required.

These cables can be installed in open air, underground, in water, indoors and in cable ducts.

The concentric conductor is permitted to be used as neutral, protective earth conductor and a screen as well.

Technical Data

- Power cables with concentric conductors, PVC insulated, PVC sheathed.

Nominal voltage Uo / U

- 0.6/1kV

Main standard

- IEC 60502 - 1

Cable code

- NYCY

- NYCWY

Temperature range

- - 30℃ to + 70℃

بدون دیدگاه