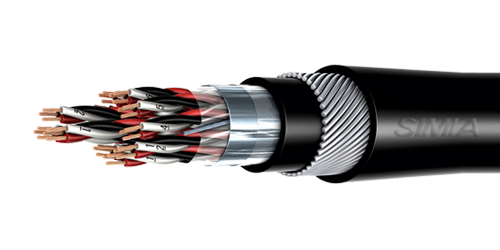

Instrumentation Cables

(PiMF, TiMF, QiMF)

| no. & nominal cross section of conductors (mm²) | Conductor class | Nominal insulation thickness(mm) | Nominal thickness of inner sheath(mm) | Nominal diameter of braid armor (mm) | Nominal thickness of sheath(mm) | Average final diameter (mm) | Max.Conductor Resistance at 20 °C | Approx.weight(Kg / Km) |

|---|---|---|---|---|---|---|---|---|

| Cu/PVC/ISCR/OSCR/PVC | ||||||||

| 2×2×0.5 | 2 | 0.52 | - | - | 1.3 | 10.7 | 36 | 118 |

| 4×2×0.5 | 2 | 0.52 | - | - | 1.4 | 12.5 | 36 | 183 |

| 8×2×0.5 | 2 | 0.52 | - | - | 1.5 | 16.7 | 36 | 315 |

| 12×2×0.5 | 2 | 0.52 | - | - | 1.6 | 19.6 | 36 | 442 |

| 24×2×0.5 | 2 | 0.52 | - | - | 1.8 | 27 | 36 | 814 |

| Cu/PVC/ISCR/OSCR/PVC/SWB/PVC | ||||||||

| 2×2×0.5 | 2 | 0.52 | 1 | 0.3 | 1.4 | 14.1 | 36 | 269 |

| 4×2×0.5 | 2 | 0.52 | 1.1 | 0.3 | 1.5 | 16.1 | 36 | 366 |

| 8×2×0.5 | 2 | 0.52 | 1.2 | 0.3 | 1.6 | 20.5 | 36 | 562 |

| 12×2×0.5 | 2 | 0.52 | 1.4 | 0.3 | 1.7 | 23.8 | 36 | 755 |

| 24×2×0.5 | 2 | 0.52 | 1.6 | 0.4 | 1.9 | 32 | 36 | 1328 |

| Cu/MGT/XLPE/ISCR/OSCR/LSZH | ||||||||

| 2×2×0.5 | 2 | 0.52 | - | - | 1.4 | 12.9 | 36 | 152 |

| 4×2×0.5 | 2 | 0.52 | - | - | 1.4 | 14.9 | 36 | 223 |

| 8×2×0.5 | 2 | 0.52 | - | - | 1.6 | 20.2 | 36 | 393 |

| 12×2×0.5 | 2 | 0.52 | - | - | 1.7 | 23.8 | 36 | 546 |

| 24×2×0.5 | 2 | 0.52 | - | - | 1.9 | 33 | 36 | 989 |

| Cu/MGT/XLPE/ISCR/OSCR/LSZH/SWB/LSZH | ||||||||

| 2×2×0.5 | 2 | 0.52 | 1.1 | 0.3 | 1.5 | 16.5 | 36 | 341 |

| 4×2×0.5 | 2 | 0.52 | 1.2 | 0.3 | 1.5 | 18.7 | 36 | 450 |

| 8×2×0.5 | 2 | 0.52 | 1.4 | 0.3 | 1.7 | 24.4 | 36 | 720 |

| 12×2×0.5 | 2 | 0.52 | 1.5 | 0.4 | 1.8 | 28.6 | 36 | 997 |

| 24×2×0.5 | 2 | 0.52 | 1.9 | 0.4 | 2.1 | 38.8 | 36 | 1705 |

It would be possible to produce all mentioned sizes in Triple & Quad form, with various types of Armour (SWA, SWB, DTA), Screen & Sheath materials (PVC, LSPVC, LSZH, PE, …)

Technical Data

- Instrumentation cables, multi core and multi pair, PVC insulated, PVC sheathed. PE, XLPE insulated, PVC sheathed is also available, with or without steel wire armor. with or without collective screen

Nominal Voltage Uo/ U:

- 90V

- 300V

- 500V

Main Standard

- BS EN 50288-7

Cable code

- PiMF

- TiMF

- QiMF

- RE-2Y(St)Y

- RE-2Y(St)YRY

- RE-2X(St)H

Temperature range

- Flexing: - 5°C to + 50°C

- Fixed installations XLPE: - 40°C to + 90°C

- Fixed installations PE: - 30°C to + 70°C

Cable Layer Construction

- Cu/PVC/OSCR/PVC

- Cu/PVC/ISCR/OSCR/PVC

- Cu/PVC/ISCR/OSCR/Bd/SWB/PVC

- Cu/PVC/ISCR/OSCR/Bd/SWA/PVC

- Cu/MGT/XLPE/OSCR/LSZH

- Cu/MGT/XLPE/ISCR/OSCR/LSZH

- Cu/MGT/XLPE/ISCR/OSCR/Bd/SWB/LSZH

- Cu/MGT/XLPE/ISCR/OSCR/Bd/SWA/LSZH

Cable Structure

- Conductor material: Annealed copper conductor class 1 ( solid ), class 2 ( stranded ) or class 5 ( flexible ) according to IEC 60228 or BS 6360.

- Core insulation: Compound type of PVC Tl1 ( BS 6746) or XLPE, High Density Polyethylene (HDPE).

- Core insulation colors: For multi core cables, color coding or number coding and for multi pair cables, color coding.

- Pair screen: If ordered, a Layer of polyester film will be applied helically over the pairs. Then a drain wire of tinned annealed copper, will be used along side and they all will be wrapped helically by aluminium foil.

- For cables with collective screen a layer of aluminium foil will be wrapped helically over the polyester tape using a drain wire of tinned annealed copper, under the foil.

- Bedding: For type 2 ( cables with steel wire armor ) an extruded bedding of type TM1 black PVC compound according to BS 6746 is applied over the polyester tape or collective screen or LSZH compound.

- Armor: wire, braid or tape galvanized steel armor.

- Outer sheath: For type 1 cables ( cables without SWA) one extruded layer of PVC TM1 or type 6 compound according to BS 6746 is applied over the polyester or collective screen tape. For type 2 cables, one extruded layer of PVC TM1 compound is applied over the galvanized steel wire armor or LSZH compound.

Application

These types of cables are suitable for data transmission and can be used in measurement and control technology such as control rooms of industrial plants and power stations. The optional static screen protects the transmission circuits against outer electrical interferences.

By using pair construction cables good crosstalk attenuation values in a unit can be achieved.

These cables are not suitable for direct connection to low impedance sources such as the public mains electricity supply.

بدون دیدگاه